Hey everyone. Today, I am excited to share my firsthand experience in provisioning the SAP Business Data Cloud (BDC) tenant.

(In case you are not yet familiar, SAP BDC is the unified foundation that brings together SAP Datasphere, SAP Analytics Cloud (SAC), and Databricks into one integrated ecosystem.)

In this short blog, I will walk you through the steps I took to provision a BDC tenant.

STEP 1 – Ordering Core Capacity Units

We began by ordering SAP BDC Core Capacity Units based on our organizational needs.

It’s crucial to size these units thoughtfully — considering SAC, Datasphere, and Databricks workloads collectively to ensure optimal performance and scalability.

STEP 2 – Order Confirmation from SAP

Once the order was placed, we received confirmation emails from SAP detailing the order processing status and next steps. These notifications are key for tracking provisioning progress.

STEP 3 – Access via SAP for Me

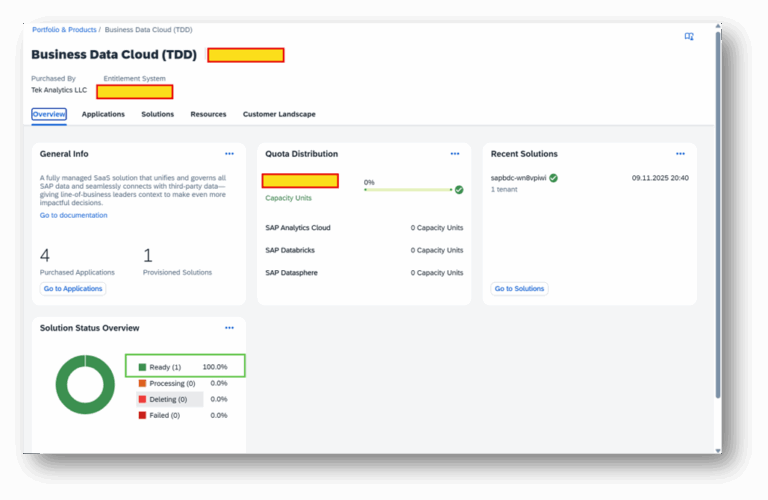

After processing, the package becomes available under your SAP for Me portal:

Portfolio & Products → My Product Packages → SAP BDC Package

This may take a few hours to reflect; once ready, you’ll notice the system status marked as “Ready.”

STEP 4 – Login and Provisioning

From there, the BDC Cockpit can be accessed using credentials provided in SAP’s confirmation email. Within the SAP for Me → BDC Product Package section, you can seamlessly start provisioning SAC, Datasphere, and Databricks — all from a unified control point.

WHAT’S NEXT

We are now in the process of migrating our existing native Databricks use cases into SAP Databricks within the BDC environment. This will unlock native data interoperability and zero-copy data sharing between SAP and Databricks, enabling advanced AI/ML and analytics use cases with full business context intact.

Stay tuned! Our upcoming blogs will dive deeper into the technical nitty-gritties of this journey, including architecture blueprints, configuration details, performance insights, and integration best practices.

Contact us today to learn more. https://tek-analytics.com/contact-tek/

By – Karthik Addula, 11/10/25

Note: Tenant was provisioned under SAP Partner Licensing.