Enabling Business Friendly Semantics in Power BI from SAP Datasphere.

As a large commercial construction company, with a long history in North America, Barton Malow is committed to building People, Projects, and Communities. While Barton Malow has been in business for over 100 years, they are not resting comfortably with past processes. Rather, Barton Malow is on a mission to transform the construction industry through innovation and increased efficiency in the building process.

To that end, they are focused on leveraging data and having a data-driven culture to aid them in their mission. However, on the journey they encountered a bit of a road bump with SAP Datasphere and Power BI.

THE PROBLEM

To get started, here is a bit of background on the situation. The Barton Malow team was facing a significant challenge with the inability to automatically feed business metadata from SAP Datasphere into Power BI. In addition, Datasphere does not check for duplication of business names (only technical names are checked) and if duplicate business names are in the same source, the Power BI load failed.

This limitation necessitated the implementation of a manual process for gathering and loading data into Power BI daily. The workaround consisted of manually pulling the metadata into a JSON file then putting through a PBI rename step. This not only increased the risk of errors but also consumed valuable time and resources, hindering the company’s ability to leverage data-driven insights effectively and efficiently.

THE SOLUTION

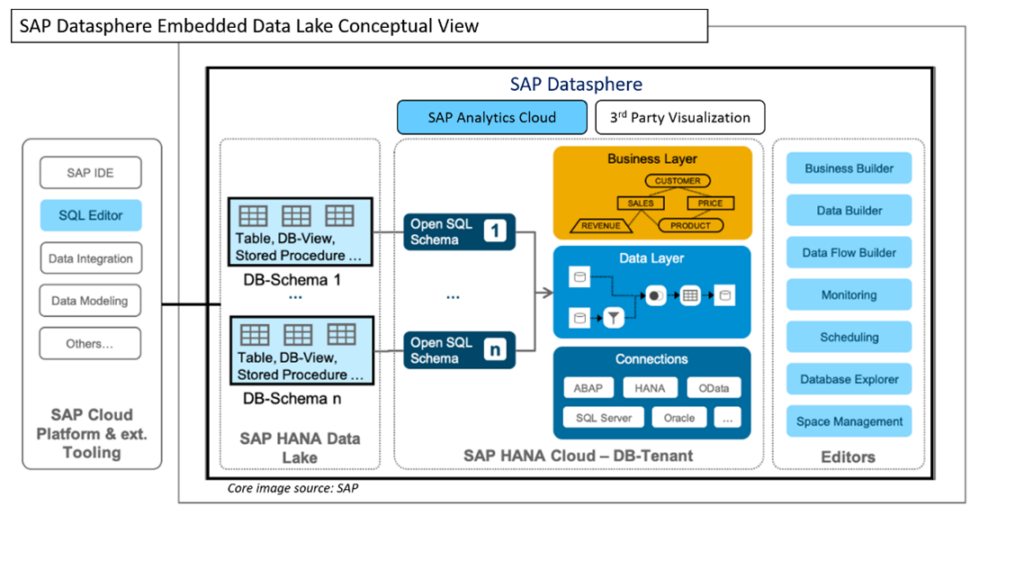

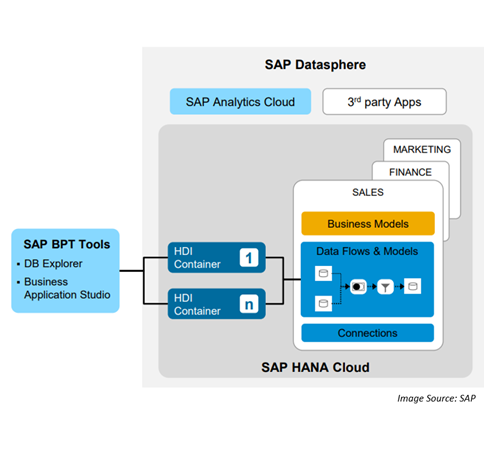

To overcome these problems, the Tek team worked with them to thoroughly understand the current situation and design an automated solution to the issues. The solution leveraged the HANA cloud directly using Business Application Studio and modeling HDI container based calculated views, which were then accessed by Power BI. This approach enabled the retrieval of business names without manual intervention.

THE RESULTS

At the end of the day, the outcome was a solution that provided:

- Improved business process efficiency with the elimination of manual processes.

- Seamless availability of business names in Power BI to support self-service and data-driven culture.

Ready to move your data strategy forward and unlock the full potential of your data? This client success story is just one example of how we help businesses modernize their data architectures, streamline operations, and drive faster decision-making.

Let us help you achieve the same success! Contact us today to discuss how we can support your migration to SAP Datasphere. Contact TEK – Tek Digital Transformations